Marine LED lighting has become the preferred choice for boat owners due to its energy efficiency, durability, and longevity in challenging marine environments. However, even the most robust LED systems can experience issues such as flickering lights, water damage, or complete failures over time. These problems can stem from factors like improper installation, voltage inconsistencies, or environmental wear and tear. Understanding how to troubleshoot these common problems is essential for maintaining a well-lit, safe, and functional vessel.

In this guide, we’ll delve into the most common marine LED lighting problems, explain their root causes, and provide actionable solutions to ensure your lighting system remains reliable for every adventure on the water.

Understanding Marine LED Lighting Systems

How Marine LEDs Differ from Standard LEDs

Marine-grade LED lighting fixtures are specifically designed to withstand harsh marine conditions, including exposure to saltwater, moisture, and vibrations. Unlike standard LEDs, marine-grade versions often feature higher waterproof ratings (IP67 or IP68), corrosion-resistant housings, and reinforced connections to ensure long-term durability and safety.

Key Components of a Marine LED System

A typical marine LED lighting system consists of fixtures, LED drivers, power supplies, wiring, and control panels. Each component plays a vital role in delivering consistent and reliable performance. Drivers regulate power to prevent damage from voltage fluctuations, while waterproof connections and seals protect against moisture ingress. A thorough understanding of these components is essential when troubleshooting lighting issues, as each part can contribute to specific problems if malfunctioning.

Common Marine LED Lighting Problems and Their Causes

Flickering Lights

Flickering LED lights are one of the most frequent issues boat owners encounter. This can be caused by voltage fluctuations, loose wiring connections, incompatible dimmers, or failing LED drivers. Corrosion on electrical contacts or poor grounding can further exacerbate the flickering, creating a frustrating and potentially unsafe situation.

Dim or Low-Output Lights

When LED lights produce a weaker-than-expected output, it’s often due to voltage drops, poor-quality LED drivers, or battery issues. Long wiring runs, insufficient battery charge, or low-quality fixtures can also result in dim lighting, reducing the effectiveness of your boat’s illumination.

Water Intrusion and Moisture Damage

Despite waterproof ratings, water can still penetrate marine LED fixtures if seals are compromised, installation is improper, or physical damage occurs. Moisture intrusion can cause short circuits, rust, or permanent damage to LED chips, leading to malfunctioning lights.

Complete Light Failure

When a marine LED fixture fails entirely, it’s often a result of power supply issues, blown fuses, faulty drivers, or burned-out LED chips. Wiring faults, such as frayed connections or corroded terminals, can also cause lights to stop functioning.

Troubleshooting Flickering Marine LED Lights

Check Voltage Stability

Voltage inconsistencies are a common cause of flickering lights. Use a multimeter to measure voltage levels at the fixture and ensure they match the LED manufacturer’s specifications. Voltage spikes or drops often point to issues with your boat’s power supply, alternator, or battery system.

Inspect Wiring and Connections

Loose or corroded wiring can interrupt the steady flow of electricity to your LED fixtures. Carefully inspect all wiring connections, terminals, and control panels for damage or rust. Tighten loose connections and clean corroded contacts using an appropriate cleaning solution.

Verify Dimmer Compatibility

Not all dimmer switches are compatible with LED systems. Ensure your dimmer switch is specifically designed for marine-grade LED fixtures. Incompatible dimmers can cause flickering or prevent LEDs from functioning correctly.

Addressing Dim or Low-Output Marine LEDs

Measure Voltage Drop Across Fixtures

Voltage drops can occur when LED fixtures are installed far from the power source or when the wiring gauge is insufficient. Use a multimeter to measure the voltage at the LED fixture. If significant drops are detected, upgrading to thicker gauge wiring or installing voltage stabilizers can improve output.

Evaluate Battery Performance

A weakened or undercharged battery may not provide sufficient power to sustain LED lights at full brightness. Check your battery’s charge level, health, and output capacity, ensuring it meets the requirements for your LED fixtures.

Inspect and Replace LED Drivers

LED drivers regulate voltage and ensure optimal power delivery. Faulty drivers can cause dim or flickering lights. If the driver shows signs of overheating, physical damage, or inconsistent output, replace it with a marine-grade driver designed for your fixtures.

Resolving Water Intrusion Issues

Inspect and Replace Damaged Seals

Water ingress often occurs when seals or gaskets become damaged, cracked, or improperly installed. Inspect the seals on all fixtures and replace them if they show signs of wear. Ensure gaskets are seated properly during reinstallation.

Dry Out Affected Fixtures

If water intrusion is detected, immediately disconnect the power and dry out the affected fixtures completely. Silica gel packs can help absorb residual moisture, and fixtures should only be reinstalled once fully dry.

Use Fixtures with Higher IP Ratings

If moisture issues persist, consider upgrading to IP68-rated marine LED fixtures, which provide higher resistance to water ingress and are better suited for underwater or exposed applications.

Fixing Complete Light Failure

Test the Power Supply and Fuses

If an LED fixture is not turning on, start by testing the power supply and inspecting fuses for damage or burnout. Replace blown fuses and ensure consistent power delivery.

Inspect LED Drivers and Chips

LED drivers and chips are susceptible to damage from power surges, moisture, and overheating. Replace faulty drivers or LED chips if they show signs of damage, such as blackened spots or burn marks.

Check Wiring for Short Circuits

Exposed or damaged wires can cause short circuits, leading to fixture failure. Carefully inspect all wiring paths and repair or replace frayed connections.

Preventing Future Marine LED Lighting Problems

Regular Maintenance Checks

Routine maintenance is crucial for ensuring long-term performance. Inspect wiring, seals, and fixtures regularly for wear, corrosion, or damage, and clean lenses to maintain brightness.

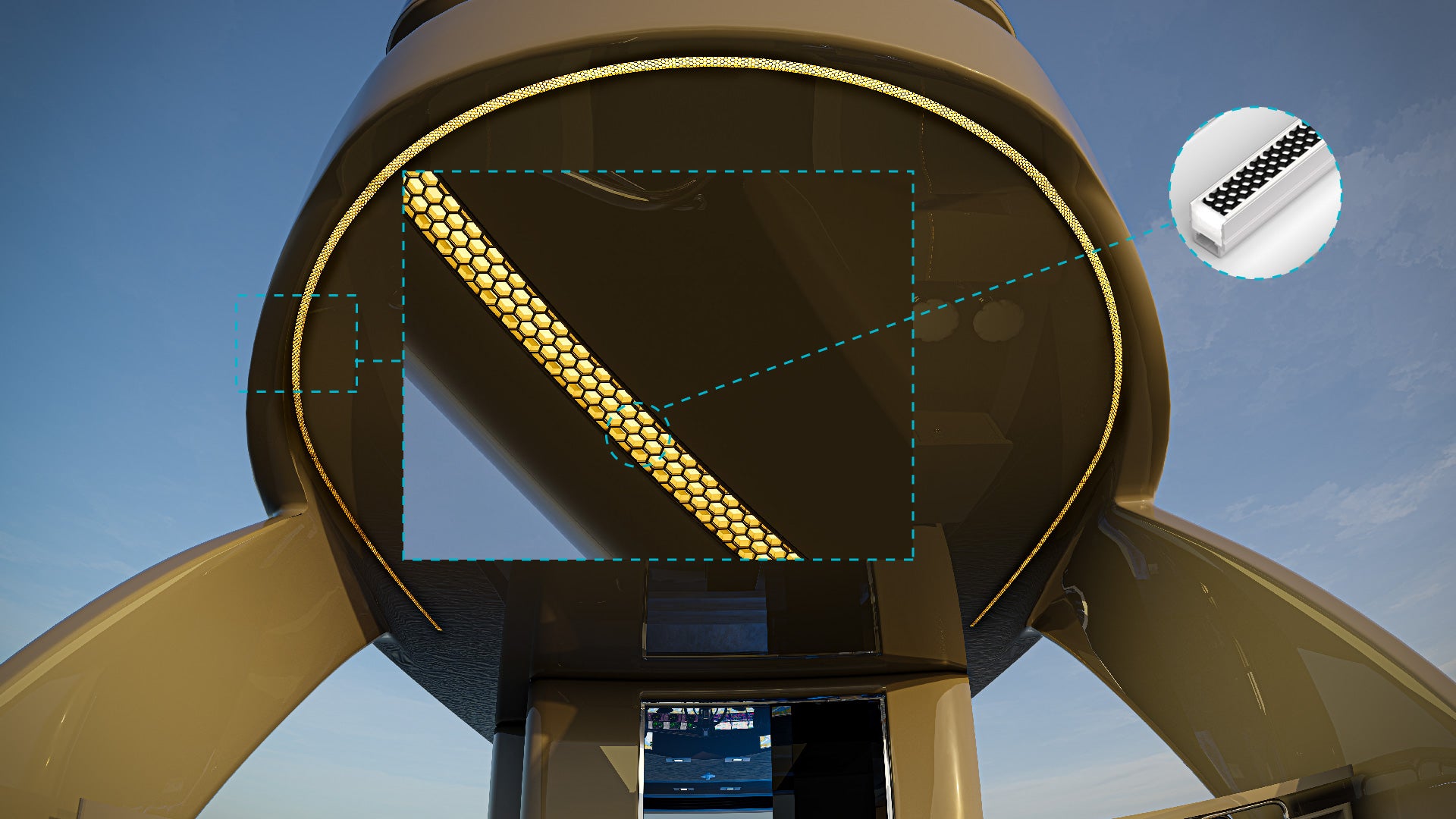

Invest in Marine-Grade Fixtures

Choosing high-quality, marine-rated fixtures with corrosion resistance and waterproof certification ensures better long-term reliability.

Monitor Battery Health

Ensure your batteries are properly charged and maintained to deliver consistent power to all LED fixtures. Faulty batteries can lead to repeated lighting problems.

When to Seek Professional Help

Complex Wiring or System Failures

If troubleshooting efforts don’t resolve the issue, or if the problem appears systemic, consult a certified marine electrician.

Persistent Lighting Problems

Chronic flickering, dimness, or repeated failures often indicate underlying electrical or structural problems that require professional intervention.

Tools You Need for Troubleshooting Marine LED Lighting

Proper troubleshooting of marine LED lighting problems requires the right set of tools to ensure safety, accuracy, and efficiency. Having these essential tools on hand not only simplifies the process but also minimizes potential damage during repairs. Below is an expanded overview of the key tools every boat owner should have in their troubleshooting kit:

Multimeter

A multimeter is an indispensable tool for diagnosing electrical issues in marine LED lighting systems. It allows you to measure voltage, current, and resistance, helping you identify problems such as voltage drops, faulty connections, or damaged drivers. When troubleshooting flickering lights, dim fixtures, or complete light failures, a multimeter helps pinpoint whether the issue lies with the power source, wiring, or LED components. For marine environments, a digital multimeter with waterproof housing is highly recommended to prevent damage from moisture exposure.

Wire Cutters and Strippers

High-quality wire cutters and strippers are essential for working with marine-grade wiring. Wire cutters allow you to trim damaged or frayed wires, while strippers ensure clean and accurate removal of insulation without damaging the conductive core. Properly cut and stripped wires make it easier to establish secure electrical connections, reducing the risk of flickering lights or short circuits. Opt for marine-grade tools with anti-corrosion coatings to ensure durability in saltwater environments.

Electrical Tape

Electrical tape is a versatile tool used to insulate and secure electrical connections, protecting them from moisture, corrosion, and short circuits. In marine environments, it’s important to use high-quality, waterproof electrical tape specifically designed to withstand salt exposure and temperature fluctuations. Proper application of electrical tape prevents exposed wiring and ensures a reliable electrical connection, even in harsh weather conditions.

Replacement Fuses

Marine LED lighting systems often include fuses as a protective measure against electrical overloads or short circuits. A blown fuse is a common cause of light failure, and having a set of replacement fuses ensures you can quickly address the issue without prolonged downtime. Always keep a variety of fuse ratings that match your LED lighting system’s specifications, and verify compatibility with your boat’s electrical setup before installation.

Heat Shrink Tubing

Heat shrink tubing is a critical component for sealing and protecting wire connections from moisture and corrosion. After making a repair or creating a new wiring connection, heat shrink tubing is applied and shrunk with heat to form a tight, waterproof seal around the connection. This not only improves the reliability of the connection but also reduces the risk of electrical shorts and corrosion-related failures. Always carry a variety of heat shrink sizes suitable for different wire gauges.

Waterproof Sealants

Waterproof sealants are essential for maintaining the integrity of lighting fixtures, gaskets, and cable entries. Over time, seals and gaskets may degrade, allowing moisture to penetrate the fixtures and damage LED chips or drivers. Marine-grade sealants create a watertight barrier around fixtures, preventing water intrusion even in rough seas. Look for marine-specific sealants that are UV-resistant and flexible, as they will endure temperature changes and prolonged sun exposure without cracking or deteriorating.

Having these tools readily available on your boat ensures that minor issues can be quickly addressed, preventing them from escalating into costly repairs. A well-prepared troubleshooting toolkit is an investment in safety, efficiency, and the longevity of your marine lighting system.

Common Myths About Marine LED Lighting

Despite their growing popularity and undeniable advantages, marine LED lighting systems are often surrounded by misconceptions and myths. These misunderstandings can lead to poor maintenance practices, incorrect installations, or unrealistic expectations. Let’s address some of the most common myths about marine LED lighting and uncover the truth behind them:

"LEDs Don’t Need Maintenance"

One of the biggest misconceptions about marine LED lighting is that LEDs are maintenance-free. While it’s true that LEDs are far more durable and long-lasting than traditional lighting technologies, they are not completely maintenance-free. Factors like salt exposure, moisture ingress, vibration, and temperature fluctuations can still cause damage over time. Regular inspections of seals, wiring, and connections are essential to ensure that fixtures remain in optimal condition. Cleaning lenses and removing salt buildup also help maintain maximum light output and clarity. Neglecting routine checks can shorten the lifespan of your LEDs, despite their inherent durability.

Reality: Marine LED lighting requires periodic maintenance and inspections to perform reliably over time.

"All LEDs Are the Same"

Another common myth is that all LED lights offer the same level of performance and durability, regardless of their intended application. However, marine-grade LEDs are specifically engineered to withstand the unique challenges of marine environments, such as high humidity, saltwater exposure, and constant vibrations from engine activity or rough waters. Standard LEDs, such as those used in homes or offices, lack the protective features needed to survive harsh marine conditions and will fail prematurely when exposed to moisture or corrosion.

Marine-grade LEDs are designed with:

- IP67 or IP68 waterproof ratings to prevent water ingress.

- Corrosion-resistant materials like stainless steel or anodized aluminum housings.

- Vibration-resistant designs to ensure stable connections in rough conditions.

Reality: Not all LEDs are built the same—marine-grade LEDs are specifically designed for durability and reliability in challenging marine environments.

"LED Lights Don’t Overheat"

While LEDs produce significantly less heat compared to traditional incandescent or halogen bulbs, they are not entirely immune to overheating. Poor ventilation, improper installation, or using fixtures in enclosed spaces without adequate airflow can lead to heat buildup. Excess heat can damage LED chips, shorten the lifespan of drivers, and reduce overall light output. Proper fixture placement and ensuring good heat dissipation are essential for preventing overheating issues.

Reality: LEDs are efficient, but improper installation or poor ventilation can still lead to overheating, affecting their performance and lifespan.

"Marine LEDs Are Only for Aesthetic Purposes"

Many people associate marine LED lighting with underwater glow effects or decorative deck lighting. While LEDs are undeniably excellent for creating ambiance, they also serve critical functional purposes. Navigation lights, task lighting, engine room illumination, and emergency lighting are all enhanced by bright, reliable, and energy-efficient LED fixtures.

Reality: Marine LEDs are not just for aesthetics—they play a vital role in safety, navigation, and operational efficiency on boats.

By dispelling these myths, boat owners can make informed decisions about their LED lighting systems, ensuring they are installed, maintained, and used correctly. Understanding the real capabilities and requirements of marine-grade LEDs can prevent avoidable failures, extend fixture lifespans, and ultimately improve the overall boating experience.

Understanding and troubleshooting marine LED lighting problems is essential for safe and efficient boating. By performing regular inspections, addressing issues early, and investing in high-quality marine-grade fixtures, you can ensure consistent performance and reliability from your lighting system.

Explore K2 Lighting's selection of durable, energy-efficient marine lighting solutions designed to withstand the harshest conditions.