As spring approaches, boat owners eagerly anticipate getting their vessels back on the water for a season of adventure and relaxation. However, before setting sail, it’s essential to perform a thorough inspection of your boat’s lighting systems. Proper lighting isn’t just about aesthetics—it’s about safety, compliance with maritime laws, and creating a seamless onboard experience. From navigation lights ensuring safe passage to deck and interior lights providing comfort and functionality, every fixture plays a role. This guide will outline various essential marine lighting checks to help you prepare your boat for a trouble-free spring season.

Why Marine Lighting Maintenance is Crucial for Spring

Ensuring Safety on the Water

Safety is the top priority for any boating experience, and functional lighting systems are a key component of that safety. Navigation lights ensure that your boat is visible to others in low-light conditions, while deck lights prevent slips and falls onboard. By inspecting and maintaining your lights before the season begins, you reduce the risk of accidents and create a safer environment for passengers and crew members alike.

Compliance with Marine Regulations

Marine regulations mandate specific requirements for lighting systems, including color, placement, and visibility range. These rules are in place to ensure safe interactions between vessels, especially in crowded or poorly lit waterways. Neglecting maintenance could result in non-compliance fines, invalidated insurance claims, or even collisions. Regular checks help guarantee that your lighting meets local and international maritime safety standards.

Extending the Lifespan of Your Lighting System

Marine lighting systems are exposed to harsh environmental conditions, including saltwater, UV rays, and temperature fluctuations. Regular inspections and maintenance prevent small issues, like corroded connectors or cracked seals, from becoming costly repairs or replacements. Proper care ensures that your lighting fixtures remain reliable season after season.

Pre-Season Inspection Checklist for Marine Lights

Exterior Lighting Inspection

Your boat’s exterior lights—including navigation, anchor, and deck lights—are constantly exposed to the elements. Over time, they may suffer from moisture ingress, UV damage, or mechanical wear. Before launching, carefully inspect each fixture for visible damage, rust, or cracks in the housing. Check that lenses are clear and free from cloudiness, as dirty or foggy lenses can significantly reduce light output. A clean and fully functional exterior lighting system is crucial for visibility and communication with other vessels.

Interior Lighting Inspection

Interior lights serve a mix of practical and aesthetic purposes, from illuminating kitchens and cabins to creating cozy relaxation zones. Test each light to ensure it operates consistently without flickering or dimming. Look for loose wiring, faulty switches, or cracked lenses, and replace any damaged components immediately. Proper interior lighting enhances onboard comfort, ensuring that living spaces remain functional and inviting throughout your trip.

Battery and Power Supply Check

Lighting systems rely on a stable and well-maintained power supply to function reliably. Begin by inspecting your boat’s batteries for proper charge levels, signs of corrosion, and secure terminal connections. Use a multimeter to test battery voltage and ensure they’re delivering sufficient power to support your lighting system. Address any wiring faults, frayed cables, or damaged connectors to prevent electrical failures during your voyages.

Checking Navigation Lights for Compliance and Functionality

Verify Proper Color and Positioning

Navigation lights follow strict guidelines regarding color, placement, and viewing angles to ensure clear communication between vessels. Verify that red, green, and white lights are installed in their correct positions and emitting the appropriate colors. Misplaced or malfunctioning lights can lead to confusion and accidents on busy waterways.

Test for Brightness and Visibility Range

Navigation lights must be bright enough to meet the visibility distance mandated by maritime regulations. Conduct a visibility test at dusk or dawn to ensure they are easily seen from the required distance. Replace any dim or failing lights to maintain compliance and safety standards.

Inspect Waterproof Seals and Housing

Water damage is one of the most common causes of lighting failure. Inspect the waterproof seals and housing of navigation lights for cracks, gaps, or signs of water intrusion. Replace worn gaskets and apply marine-grade sealants if necessary to ensure a watertight seal.

Deck and Work Light Functionality

Illuminate Key Areas for Safety and Accessibility

Deck lights are essential for safe navigation and task management at night. Check that they illuminate key areas, such as walkways, stairs, and mooring points, effectively. Proper deck lighting prevents slips, falls, and injuries during night operations.

Evaluate Beam Angle and Light Spread

Proper beam angles and light distribution ensure that deck lights cover their intended areas without creating harsh glare or blind spots. Adjust fixtures if necessary to maximize efficiency and minimize wasted light.

Waterproof and Corrosion Resistance Test

Deck lights are exposed to constant moisture, salt spray, and UV rays, making waterproofing and corrosion resistance essential. Inspect housings for rust, pitting, or water damage, and replace compromised fixtures immediately to avoid sudden failures.

Inspecting Underwater Lights

Check for Cracks or Leaks in Fixtures

Underwater lights are often exposed to high water pressure and physical impacts. Carefully inspect each fixture for cracks or signs of water ingress. Damaged lights can pose safety risks and compromise your boat's aesthetics.

Ensure Proper Wiring and Connection Security

Underwater lights rely on secure wiring and robust seals to function effectively. Check all wiring connections for tightness and waterproof integrity. Loose or frayed wires can lead to failures or short circuits.

Test Brightness and Color Consistency

Underwater lights should emit a consistent level of brightness and uniform color output. Fading or flickering lights may indicate electrical issues or damage to the LED chips, requiring replacement.

Interior and Cabin Lighting Checks

Verify Functionality in All Fixtures

Interior cabin lights play an essential role in ensuring comfort, usability, and ambiance. Check every fixture for flickering, dimming, or failure to turn on. Replace bulbs or fixtures showing signs of malfunction.

Optimize Lighting Placement for Comfort

Evaluate whether your current lighting setup meets your needs. Consider installing adjustable or dimmable fixtures for more flexibility in task lighting and ambient lighting settings.

Check Power Efficiency

Interior lights should consume minimal power to preserve battery life. Switch outdated bulbs to energy-efficient marine-grade LEDs if they are not already installed.

Verify Anchor and Mooring Lights

Check for Proper Placement and Visibility

Anchor lights must be clearly visible from all directions when stationary. Test them for brightness and ensure compliance with visibility standards.

Test for Continuous Operation

Anchor lights should remain operational for extended overnight use. Test battery drain and ensure the light remains steady and bright over long durations.

Assess Backup and Emergency Lighting

Verify Emergency Light Availability

Backup lights are critical for power outages or emergency evacuations. Ensure they are easy to access and fully functional.

Test Battery-Powered Backup Systems

Check standalone battery-powered lights for reliability and battery longevity. Replace worn-out batteries and faulty fixtures immediately.

Cleaning and Maintenance of Marine Lights

Remove Salt and Debris Build-Up

Salt, grime, and debris can obstruct light output and damage fixtures. Clean lenses and housings with marine-safe solutions regularly.

Inspect and Replace Gaskets and Seals

Check gaskets for wear and apply fresh sealant where necessary to maintain waterproofing.

Upgrade Outdated Marine Lighting Fixtures

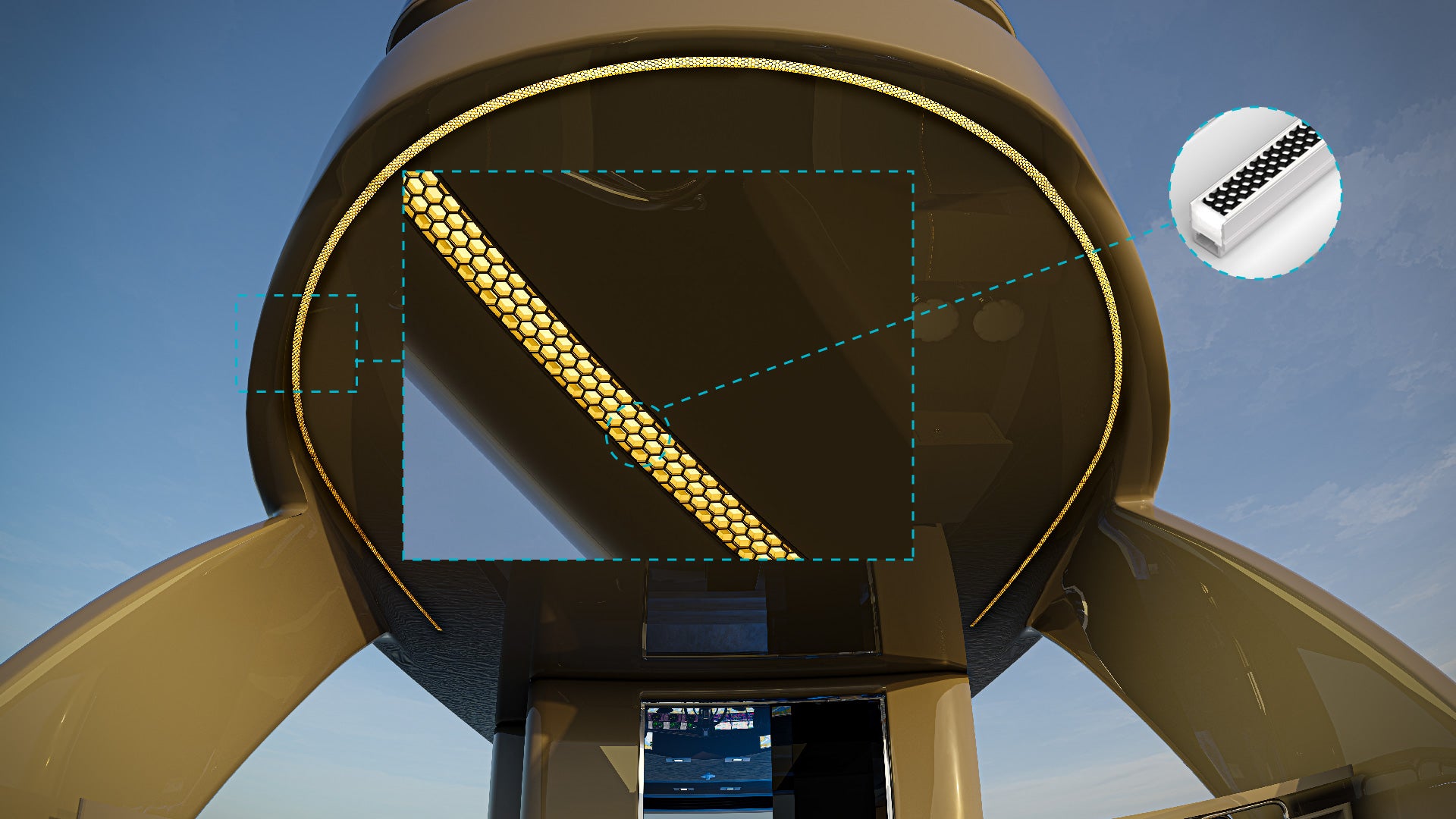

Switch to Marine-Grade LED Lights for Enhanced Performance

Upgrading your boat’s lighting system to marine-grade LED lights is one of the most impactful improvements you can make for performance, efficiency, and reliability. Unlike traditional halogen or incandescent lights, marine-grade LEDs are specifically designed to withstand harsh marine environments, including constant exposure to salt spray, humidity, UV rays, and temperature fluctuations. Their energy efficiency is unparalleled, consuming up to 80% less power than older lighting technologies, which significantly reduces battery strain during long trips.

LEDs also produce brighter and more focused illumination with minimal heat generation, which makes them safer and more effective in confined spaces like cabins or engine rooms. They have an average lifespan of up to 50,000 hours, meaning fewer replacements and reduced long-term costs. Another advantage of marine-grade LEDs is their resistance to vibrations and shocks, ensuring reliable operation even in rough waters or turbulent conditions.

When upgrading, focus on key lighting zones:

- Navigation Lights: Ensure compliance with maritime regulations while benefiting from brighter, clearer light output.

- Deck and Walkway Lights: Enhance safety with evenly distributed, anti-glare lighting.

- Cabin and Interior Lights: Create a more comfortable and inviting atmosphere with dimmable options and adjustable color temperatures.

Investing in marine-grade LEDs isn’t just about aesthetics—it’s about long-term performance, safety, and energy savings that significantly improve your boating experience.

Explore Smart Lighting Systems for Remote Control and Automation

Smart marine lighting systems are revolutionizing how boat owners control and customize their onboard illumination. With advancements in lighting technology, many marine-grade LED systems now feature smart controls, remote access, and automation options. These systems allow you to adjust brightness, change colors, and set timers through mobile apps or dedicated remote controls, offering unparalleled convenience and efficiency.

For example:

- Remote Control Access: Easily turn on or off lights, adjust brightness, or switch between lighting zones without manually accessing switches.

- Automated Timers: Schedule specific lights to turn on at dusk or turn off automatically after a certain time, optimizing energy usage.

- Motion Sensors: Activate lights only when movement is detected, which is particularly useful for deck pathways or security zones.

Smart systems also allow for customizable lighting zones, letting you adjust different areas of your boat independently. For instance, you might want bright white lights on the deck for safety while maintaining warm ambient lighting inside the cabin for relaxation.

These systems are not just about convenience—they also enhance security. With remote monitoring, you can check your boat’s lighting status from your phone and ensure lights are turned off when not in use, preventing unnecessary battery drain. Smart lighting represents the future of marine illumination, offering control, customization, and efficiency like never before.

Create a Seasonal Marine Lighting Maintenance Schedule

Plan Pre-Season, Mid-Season, and Post-Season Inspections

A seasonal maintenance schedule ensures that your marine lighting systems remain in optimal condition throughout the year. Dividing inspections into pre-season, mid-season, and post-season checks allows you to address potential issues proactively, rather than waiting for problems to arise while you’re out on the water.

- Pre-Season Inspections: Before launching your boat in spring, inspect all lighting fixtures for damage, corrosion, and water ingress. Test navigation lights, deck lights, underwater lights, and cabin fixtures for brightness and consistency. Replace worn gaskets, seals, or connectors and clean lenses to ensure maximum light output.

- Mid-Season Inspections: Midway through the boating season, perform a brief check to identify any issues that may have developed. Pay special attention to exterior lights exposed to saltwater and sun damage. Test batteries, ensure wiring connections remain tight, and clean fixtures of accumulated salt or grime.

- Post-Season Inspections: At the end of the boating season, conduct a thorough inspection before winterizing your vessel. Look for corrosion, cracked housings, or loose seals. Remove and store removable fixtures in a dry, climate-controlled space to extend their lifespan.

A structured schedule ensures small problems are caught early, preventing expensive repairs or lighting failures during critical moments on the water.

Stock Essential Spare Parts, Bulbs, and Connectors

Having a stock of essential lighting spare parts onboard is one of the simplest ways to avoid downtime caused by unexpected failures. Marine lighting systems can be subject to wear and tear, harsh weather, and accidental damage, and having the right replacement parts on hand can save time and frustration during repairs.

Key spare parts to keep onboard include:

- Replacement LED Bulbs: Even though LED bulbs have a long lifespan, having spares is useful in case of accidental damage or unexpected failure.

- Fuses and Connectors: Electrical surges or short circuits can damage fuses, so having spares ensures quick repairs.

- Waterproof Sealants and Gaskets: These are essential for maintaining watertight seals in lighting fixtures exposed to moisture.

- Multimeter: An essential tool for troubleshooting voltage and connection issues.

Store these parts in a waterproof container and ensure they are organized and labeled for easy access. This preparedness ensures you can handle minor repairs and replacements efficiently, minimizing disruptions during your boating adventures.

Common Myths About Marine Lighting

"LED Lights Don’t Need Maintenance" – Regular Checks Prevent Failure

One of the most common misconceptions is that LED lights are entirely maintenance-free. While it’s true that marine-grade LED lights are far more durable and long-lasting than traditional options, they are still exposed to environmental challenges such as saltwater, UV rays, vibrations, and moisture intrusion.

Regular maintenance is essential to ensure consistent performance and prevent avoidable failures. Tasks such as cleaning light lenses, checking seals, inspecting for corrosion, and securing wiring connections are vital for maintaining peak functionality. Ignoring these routine tasks can lead to premature failure or reduced performance, despite the inherent durability of LEDs.

"All Marine Lights Are the Same" – High-Quality Marine-Grade LEDs Outperform Standard Fixtures

Not all marine lights are created equal, and assuming they are can lead to costly mistakes. Standard LEDs might offer brightness and low energy consumption, but they often lack the rugged build quality, corrosion resistance, and waterproof seals necessary for marine environments.

High-quality marine-grade LED lights are specifically designed for:

- Waterproof Protection: Rated IP67 or IP68 for reliable performance in wet conditions.

- Corrosion Resistance: Built with materials like stainless steel or anodized aluminum to resist saltwater exposure.

- Shock and Vibration Resistance: Engineered to remain stable on rough waters.

Using standard, non-marine-grade LEDs in these conditions often results in shortened lifespans, inconsistent performance, and frequent replacements. Investing in certified marine-grade LED fixtures ensures that your lighting system is both reliable and long-lasting.

Upgrading outdated fixtures, implementing a structured maintenance schedule, and dispelling common myths about marine lighting are crucial steps for preparing your boat for spring. With marine-grade LED lighting systems, you’ll enjoy enhanced safety, efficiency, and peace of mind on every voyage.

Explore K2 Lighting's range of durable waterproof LED lighting solutions for your Spring upgrades.