Investing in high-quality marine LED lighting is one of the smartest upgrades you can make for your vessel. But without proper maintenance and corrosion protection, even the most premium marine LEDs can fall victim to the relentless assault of saltwater, UV radiation, and marine environments. The good news? With the right knowledge and maintenance routine, your marine LED investment can provide years of reliable, brilliant illumination.

At K2 Lighting, we've spent over a decade engineering marine LED solutions that stand up to the harshest conditions. Through extensive testing and real-world applications, we've learned what it takes to protect your lighting investment and maximize its lifespan. Let's explore the essential strategies for keeping your marine LEDs performing at their peak.

Understanding the Enemy: How Saltwater Attacks Your Lighting

Saltwater is one of nature's most aggressive environments for electrical equipment. The combination of salt, moisture, and oxygen creates an electrochemical reaction that accelerates corrosion exponentially compared to freshwater environments. When you add UV radiation, temperature fluctuations, and constant vibration from wave action, you have a perfect storm for equipment failure.

Marine LED lights typically face their greatest challenges at vulnerable connection points where electrical terminals become corroded, leading to voltage drops and dangerous overheating. Water intrusion through damaged wire insulation compounds these problems, while galvanic corrosion between dissimilar metals can cause rapid deterioration of mounting hardware and fixtures.

The housing and sealing systems represent another critical vulnerability. Over time, UV radiation degrades gaskets and seals, allowing saltwater to infiltrate the most sensitive internal components. Corrosion around mounting points weakens structural integrity, while salt crystal buildup interferes with proper heat dissipation, causing premature LED failure.

The K2 Lighting Advantage: Built-In Protection

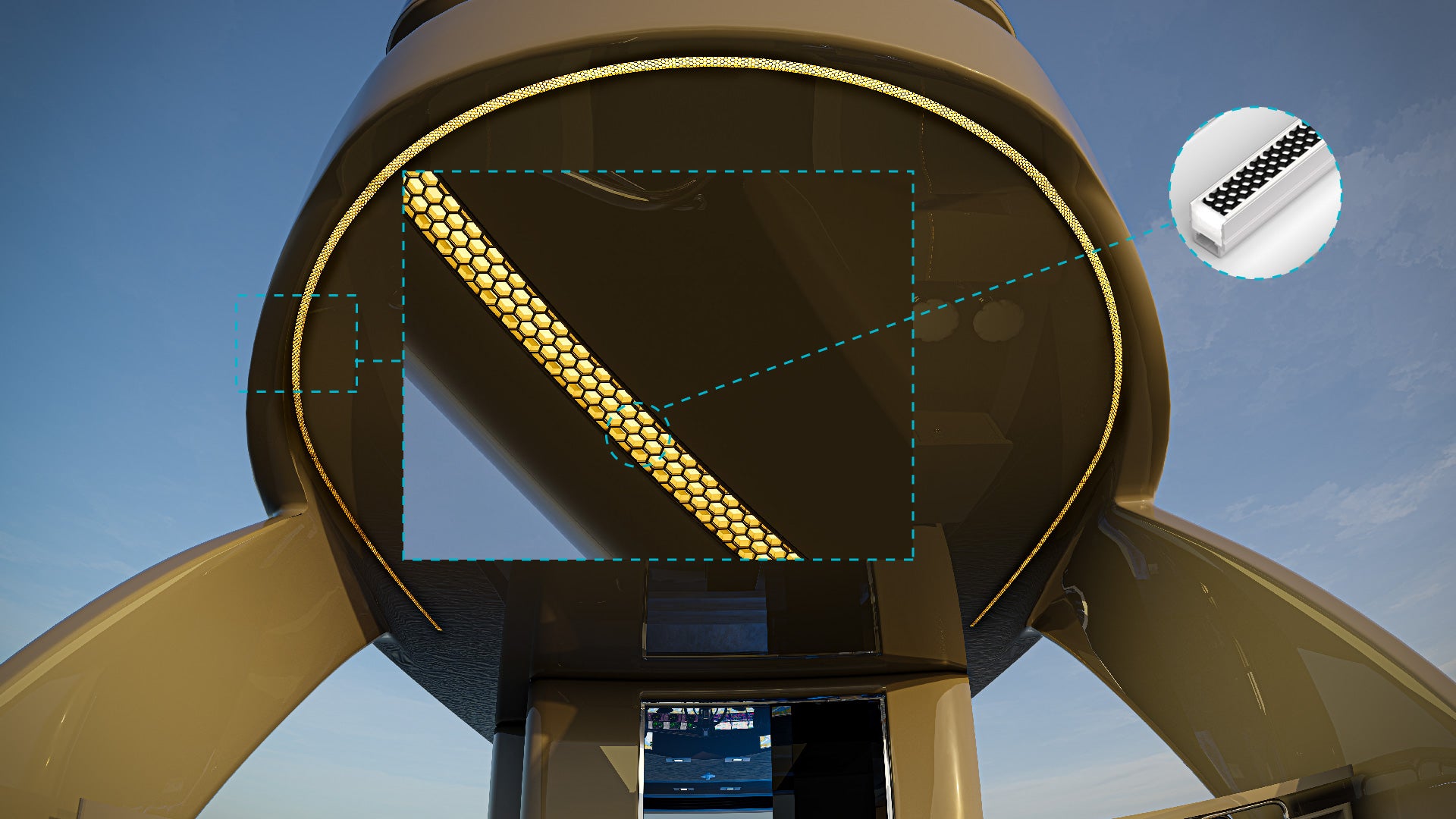

K2 Lighting's marine LED fixtures incorporate multiple layers of protection specifically engineered for marine environments. Our commitment to using marine-grade materials means every component is selected for its ability to withstand saltwater exposure. We utilize 316 stainless steel components for superior corrosion resistance, while our anodized aluminum housings provide a protective oxide layer that prevents corrosion while maintaining optimal heat dissipation.

Understanding IP ratings is crucial for marine applications, and K2 Lighting offers various protection levels to match your specific exposure requirements. IP65-rated fixtures provide protection against water jets from any direction, making them suitable for covered deck areas. IP67 protection guards against temporary submersion, ideal for exposed deck lighting, while IP68-rated fixtures can withstand continuous submersion, perfect for underwater applications.

Our marine-grade silicone seals resist UV degradation and maintain flexibility through extreme temperature variations. Perhaps most importantly, our circuit boards feature conformal coatings that create a protective barrier against moisture infiltration, ensuring reliable operation even in high-humidity marine environments.

Essential Maintenance Practices

Developing a consistent inspection routine forms your best defense against corrosion damage. During each outing or weekly if your vessel remains docked, perform visual inspections that can catch problems before they become costly failures. Look for any discoloration around fixtures that might indicate the early stages of corrosion, check for cracks or damage in housing materials, and examine mounting hardware for signs of rust or loosening.

Beyond visual inspection, functional testing reveals electrical issues before they cause complete system failure. Test all lighting functions including color changes and dimming capabilities. Watch for flickering or reduced brightness that might indicate developing electrical problems, and verify that beam patterns haven't changed due to lens damage or internal component shifts.

Monthly deep cleaning goes beyond basic inspection to actively remove salt buildup and contaminants that accelerate corrosion. Begin by turning off all electrical power to lighting circuits and allowing fixtures to cool completely if they've been recently used. Start with a gentle freshwater rinse to remove surface salt, followed by cleaning with a mild marine-safe soap solution to break down salt crystals and organic buildup.

Pay special attention to optical surfaces, cleaning lenses with appropriate cleaners and microfiber cloths to maintain light output and beam quality. After thorough rinsing to remove all soap residue, ensure complete drying using compressed air or natural air drying before re-energizing the system. This process not only maintains appearance but significantly extends the operational life of your lighting investment.

Seasonal Maintenance Strategies

Spring preparation requires comprehensive inspection after months of winter weather exposure. Check all gaskets and seals for damage that might have occurred during harsh winter conditions. Clean and treat electrical connections with marine-grade dielectric grease, which creates a moisture barrier while maintaining electrical conductivity. Inspect and tighten all mounting bolts and brackets, as thermal cycling can cause hardware to loosen over time.

Summer monitoring becomes critical as increased temperatures and usage patterns stress your lighting systems. Hot weather requires attention to heat dissipation, ensuring ventilation areas remain clear of debris that could cause overheating. UV exposure intensifies during summer months, making it important to apply UV protectants to plastic components when recommended by the manufacturer.

Fall winterization provides an opportunity for thorough preparation before storage or reduced usage periods. Perform deep cleaning to remove accumulated salt and contaminants, apply corrosion inhibitors to exposed metal surfaces, and ensure all fixtures are completely dry before covering or storing. This preparation significantly reduces corrosion activity during periods when regular inspection might be less frequent.

Advanced Protection Strategies

Professional-grade protective treatments can significantly extend the life of your marine lighting investment. Marine-grade dielectric grease applied to all electrical connections creates an effective moisture barrier that should be reapplied annually or whenever connections are disturbed. Quality marine corrosion inhibitor sprays provide additional protection for exposed metal surfaces by creating a thin protective film that displaces moisture and prevents oxidation.

Environmental factors play a crucial role in lighting longevity. Strategic placement of fixtures to minimize direct exposure to spray and standing water benefits even marine-rated equipment. Ensure mounting locations allow proper drainage, as standing water accelerates corrosion even on protected surfaces. Adequate airflow around fixtures prevents moisture buildup while aiding cooling, which extends LED operational life.

When choosing protective coatings, consider the specific environmental challenges your vessel faces. Boats operating in tropical climates need enhanced UV protection, while vessels in colder climates require treatments that remain flexible at low temperatures. Understanding your operating environment helps determine the most effective protection strategy.

Troubleshooting and Professional Support

Early warning signs often provide opportunities to address problems before they become expensive failures. Flickering or dimming typically indicates corroded connections or moisture in electrical components and should be addressed immediately. Reduced light output may signal LED degradation or optical surface contamination, often resolved through proper cleaning procedures. Color temperature changes can indicate LED driver issues or thermal problems requiring professional evaluation.

While many maintenance tasks can be performed by boat owners, certain situations require professional attention. Internal moisture or condensation in sealed fixtures, electrical connections showing significant corrosion, physical damage to housing or mounting systems, and persistent operational issues after cleaning all warrant expert evaluation.

Maximizing Your Investment Through Proper Care

The financial benefits of regular maintenance become clear when compared to replacement costs. Monthly cleaning requires only one to two hours of labor, while seasonal maintenance involves four to six hours plus materials costing approximately fifty to one hundred dollars. Annual professional inspection adds another two to four hundred dollars, bringing total annual maintenance investment to three to six hundred dollars.

Compare this modest investment to replacement costs where quality marine LED fixtures range from two hundred to eight hundred dollars each, plus installation labor of one to three hundred dollars per fixture. Complete vessel lighting replacement often costs five to fifteen thousand dollars, making the maintenance investment pay for itself many times over.

K2 Lighting's decade of marine lighting expertise means we understand the real-world challenges your fixtures face. Our customer support team, available Monday through Friday from 8am to 5pm PST, provides technical guidance for maintenance procedures, troubleshooting assistance for performance issues, and professional service referrals when needed.

Creating Your Maintenance Success Plan

Proper documentation creates accountability and helps identify patterns that might indicate developing problems. Maintain detailed records of cleaning dates and procedures performed, inspection findings and corrective actions taken, parts replaced and warranty claims filed, and any performance changes or issues noted over time.

Your marine LED lighting represents a significant investment in safety, functionality, and enjoyment of your vessel. The marine environment will test every component, but with proper understanding and consistent maintenance, your K2 Lighting fixtures can provide decades of reliable service.

Remember that maintenance is far more cost-effective than replacement. A systematic approach to corrosion protection and preventive care ensures your lighting system continues to illuminate your marine adventures for years to come. The key is consistency through regular inspection, proper cleaning, and prompt attention to issues as they arise.

Ready to protect your marine LED investment? Contact K2 Lighting for personalized maintenance guidance and professional support. Our team is here to help you maximize the value and performance of your marine lighting system.

K2 Lighting has been manufacturing premium marine LED lighting solutions for over a decade. Our commitment to quality, durability, and customer support ensures your lighting investment delivers maximum value throughout its extended lifespan.