Marine workshops and boat garages serve as essential spaces for vessel maintenance, repairs, and storage. These environments require specialized lighting systems capable of handling unique challenges, including high humidity, exposure to saltwater, confined spaces, and the need for precision in detailed tasks. Poor lighting not only hinders productivity but can also lead to safety hazards, costly errors, and unnecessary strain on both workers and equipment.

Investing in a well-planned lighting system goes beyond just installing bright bulbs—it involves choosing durable fixtures, optimizing placement, and balancing ambient, task, and accent lighting. Marine-grade LED lighting has emerged as the preferred choice due to its durability, energy efficiency, and adaptability to harsh conditions.

In this blog, we’ll explore the science, strategy, and practical steps needed to design the best lighting setup for marine workshops and boat garages, ensuring safety, efficiency, and long-term cost savings.

Why Proper Lighting Matters in Marine Workshops and Boat Garages

Ensuring Precision and Accuracy

Marine workshops are hubs for detailed, hands-on tasks, such as engine repairs, electrical work, welding, and fiberglass restoration. Each of these activities requires focused, well-distributed lighting to ensure clarity and precision. Poor lighting can lead to mistakes that compromise safety, waste materials, or require rework, adding unnecessary costs and delays. Marine-grade LED task lights, with their high lumen output and adjustable fixtures, provide the crisp, clear illumination needed for intricate tasks, reducing errors and improving overall work quality.

Enhancing Safety in Hazardous Environments

Workshops and garages often feature sharp tools, heavy machinery, oily floors, and tight spaces—all potential hazards in poorly lit conditions. Shadows, dark corners, and inconsistent lighting can obscure these risks, increasing the likelihood of accidents. Proper lighting setups eliminate these dangers by ensuring that every workspace, walkway, and storage area is uniformly illuminated. Additionally, LED lighting systems are designed with minimal heat emission, reducing the fire risk associated with older halogen fixtures.

Improving Energy Efficiency and Cost Savings

Energy efficiency is a critical consideration in marine workshops and boat garages, where lighting systems often run for extended hours. Traditional lighting options, such as halogen or fluorescent bulbs, consume excessive power, generate heat, and require frequent replacements. Marine-grade LED lights, on the other hand, consume significantly less energy while delivering brighter and more consistent illumination. The reduced energy draw not only minimizes operational costs but also decreases reliance on fuel-powered generators in off-grid scenarios, making LEDs an eco-friendly and cost-effective choice.

Key Lighting Requirements for Marine Workshops and Boat Garages

Task Lighting for Detailed Work

Task lighting is essential for workstations where precision tasks are carried out, such as engine inspections, electrical wiring, or small component repairs. Adjustable LED task lights with focused beams and high CRI (Color Rendering Index) ensure that every detail is visible, even in the smallest crevices. These fixtures often come with flexible arms or swivel heads, allowing workers to direct light exactly where it’s needed without creating unnecessary shadows.

Ambient Lighting for General Visibility

Ambient lighting serves as the foundation of a well-lit marine workshop, ensuring broad, even illumination across the space. Overhead LED panels or high-output floodlights are ideal for providing consistent lighting without creating harsh glare. Proper ambient lighting eliminates dark zones and ensures workers can move safely and confidently throughout the workspace, even in areas without direct task lighting.

Accent Lighting for Critical Areas

Accent lighting focuses on illuminating hard-to-reach or frequently overlooked areas, such as under cabinets, inside tool drawers, or behind workbenches. Flexible LED strip lights or small directional spotlights are perfect for these spaces, providing targeted illumination without consuming excessive power. These lights ensure that every corner of the workshop remains functional and accessible, even in tight spaces.

Emergency and Backup Lighting

Power outages or equipment failures can bring workshop operations to a standstill. Emergency LED lighting systems equipped with backup batteries ensure critical visibility during unexpected power losses. These fixtures often activate automatically, providing reliable illumination for safe evacuation, quick troubleshooting, or the continuation of essential tasks.

Choosing the Right Lighting Fixtures for Marine Workshops

IP-Rated Waterproof Fixtures

Marine workshops are inherently damp and prone to water exposure from splashes, leaks, or high humidity. Lighting fixtures with high IP ratings (e.g., IP67 or IP68) ensure protection against water ingress and dust accumulation. Waterproof LED lights maintain performance and structural integrity even in the harshest marine conditions, reducing the need for frequent replacements.

Corrosion-Resistant Materials

Saltwater exposure can rapidly corrode metal fixtures and degrade electrical components. Marine-grade LED lights are often made from 316 stainless steel or marine-grade aluminum, materials specifically chosen for their resistance to rust and chemical corrosion. Protective coatings and sealed enclosures further safeguard these fixtures, ensuring they withstand years of exposure without compromising performance.

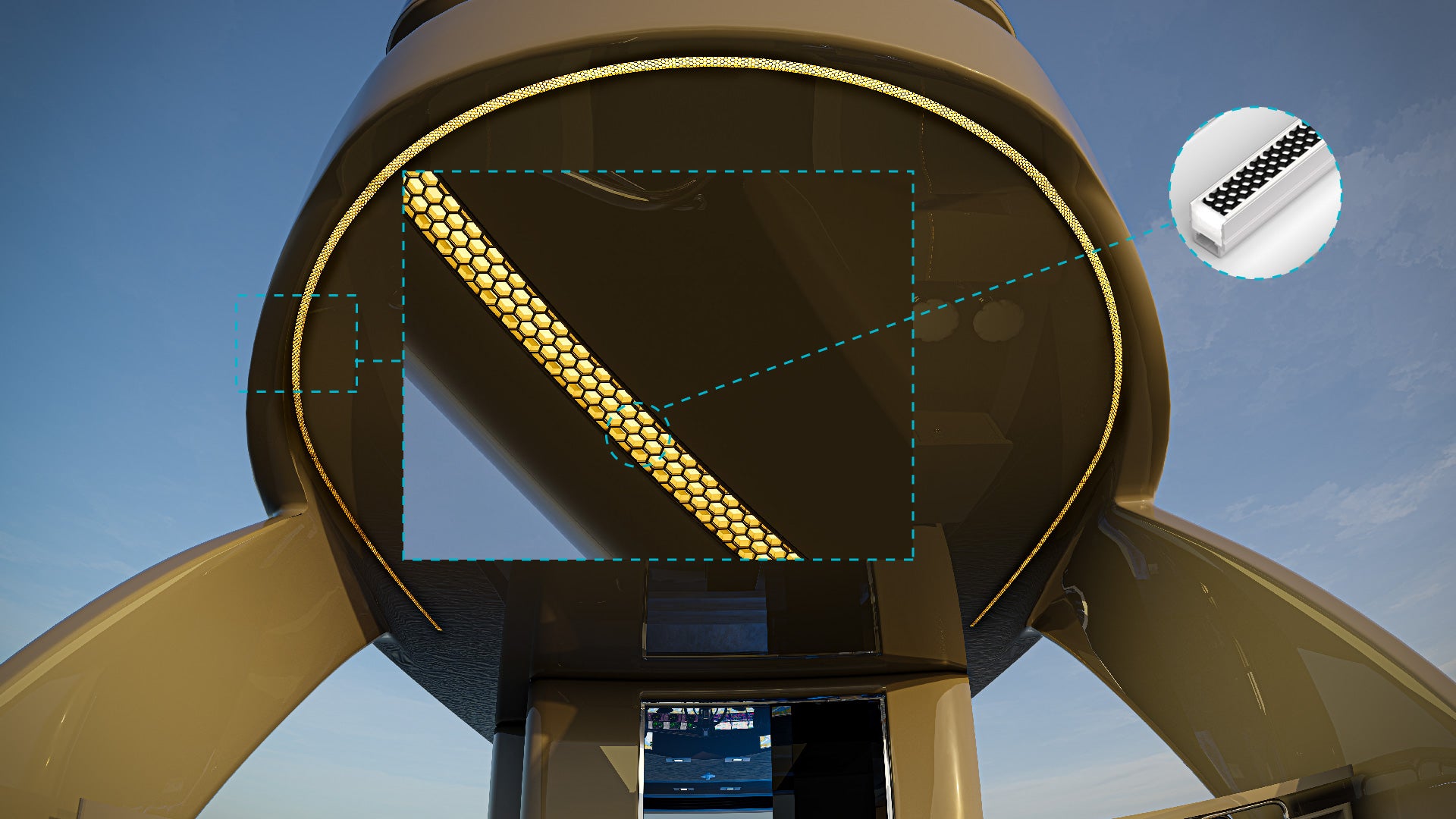

Adjustable and Directional Lights

In workshops, lighting needs often vary depending on the task at hand. Adjustable and directional LED fixtures offer unparalleled flexibility, allowing users to focus beams on specific areas or redirect light as needed. Whether mounted on workbenches, ceilings, or portable stands, these fixtures provide adaptability for various tasks without requiring additional installations.

LED Panel Lights for Wide Coverage

For large marine workshops and garages, LED panel lights are an excellent choice for providing uniform, glare-free illumination across expansive spaces. These fixtures are energy-efficient, easy to install, and distribute light evenly without creating hotspots or dark areas.

Lighting Placement Strategies for Optimal Illumination

Overhead Lighting for General Illumination

Overhead lighting forms the backbone of workshop visibility, ensuring bright and even illumination across the space. Installing marine-grade LED floodlights or panels at strategic intervals prevents shadows and ensures every corner is well-lit.

Workstation-Specific Lighting

Each workstation in a marine workshop has unique lighting requirements. Adjustable LED task lights should be installed directly above or beside workbenches, machinery, and repair zones. These fixtures reduce eye strain and improve precision by eliminating shadows and hotspots.

Under-Cabinet and Nook Lighting

Storage areas, under-cabinet spaces, and tool drawers often suffer from poor lighting, leading to wasted time searching for tools or materials. Installing LED strip lights or compact directional fixtures in these zones ensures clear visibility without additional clutter.

Portable and Mobile Lights

Workshops often require flexibility, especially when dealing with different boat sizes or repair tasks. Portable LED floodlights and mobile task lights allow workers to move light sources where they’re needed most, reducing reliance on fixed installations.

Energy Efficiency Considerations for Marine Workshop Lighting

LED Technology for Reduced Power Consumption

LED fixtures consume significantly less power than fluorescent or halogen bulbs while providing brighter and more consistent light output.

Dimmable Lighting Options

Dimmable LEDs allow workers to adjust brightness based on the task at hand, conserving energy during low-demand periods.

Smart Lighting Controls and Automation

Smart systems enable automated schedules, motion sensors, and remote control, optimizing energy usage while reducing unnecessary power consumption.

Maintenance Tips for Marine Workshop Lighting

Regular Cleaning and Inspections

Keep fixtures clean from salt deposits, dust, and grease to maintain optimal light output.

Check for Corrosion and Damage

Regularly inspect fixtures for corrosion, loose wiring, or cracks in waterproof seals.

Ensure Proper Installation

Proper installation prevents water ingress and extends fixture lifespan.

Investing in a well-designed lighting system for marine workshops and boat garages enhances safety, productivity, and cost efficiency. By understanding lighting types, placement strategies, and energy-efficient technologies, boat owners can create an optimal working environment tailored to their needs.

Explore K2 Lighting's durable, energy-efficient lighting systems designed for marine workshops and garages.