Flexible silicone lighting has emerged as a transformative technology in the lighting industry, offering unparalleled versatility and resilience. Made from robust silicone materials, these lighting solutions are designed to endure harsh environments, including exposure to moisture, dust, and extreme temperatures. This durability, combined with the flexibility of the silicone material, allows for innovative lighting designs that can enhance the aesthetic and functionality of various spaces.

Lighting plays a crucial role in setting the ambiance and improving the usability of spaces, understanding the different types of bends in silicone strip lighting is essential. Whether you’re an architect, interior designer, or DIY enthusiast, knowing when to use top bend, side bend, or 3D bend silicone lighting can significantly impact the success of your lighting projects. This blog will delve into each type, exploring their unique characteristics, advantages, and ideal applications to help you make informed decisions for your next project.

Understanding Flexible Silicone Lighting

Flexible silicone lighting is a versatile lighting solution made from durable silicone material. This type of lighting is known for its ability to withstand harsh environments, including moisture and extreme temperatures, making it suitable for both indoor and outdoor use.

Benefits and Common Uses:

- Durability: Resistant to water, dust, and UV rays.

- Flexibility: Can be shaped and bent to fit various contours and spaces.

- Energy Efficiency: LED technology ensures low energy consumption.

- Aesthetic Appeal: Provides a sleek, modern look.

Flexible silicone lighting is commonly used in architectural lighting, accent lighting, signage, and decorative lighting applications.

Top Bend

Top bend silicone lighting refers to strips that bend upwards or downwards, allowing for vertical flexibility. This type of bend is ideal for applications where the light needs to follow the contours of surfaces that change elevation.

Advantages and Ideal Applications:

- Uniform Light Distribution: Ensures even illumination along the length of the strip.

- Ideal for Under-Cabinet Lighting: Provides focused light on work surfaces without glare.

- Architectural Details: Enhances the appearance of architectural features by following their vertical contours.

Example Applications:

- Under-cabinet lighting in kitchens

- Illuminating staircases and steps

- Highlighting vertical architectural features

Side Bend

Side bend silicone lighting refers to strips that bend sideways, allowing for horizontal flexibility. This type of bend is suitable for applications where the light needs to follow curves or angles along a flat surface.

Advantages and Ideal Applications:

- Flexible Installation: Easily bends around corners and edges.

- Ideal for Signage: Provides clean, continuous illumination around letters and shapes.

- Edge Lighting: Enhances the edges of surfaces and structures for a dramatic effect.

Example Applications:

- Signage and channel letters

- Edge lighting for shelves and displays

- Creating outlines for shapes and designs

3D Bend

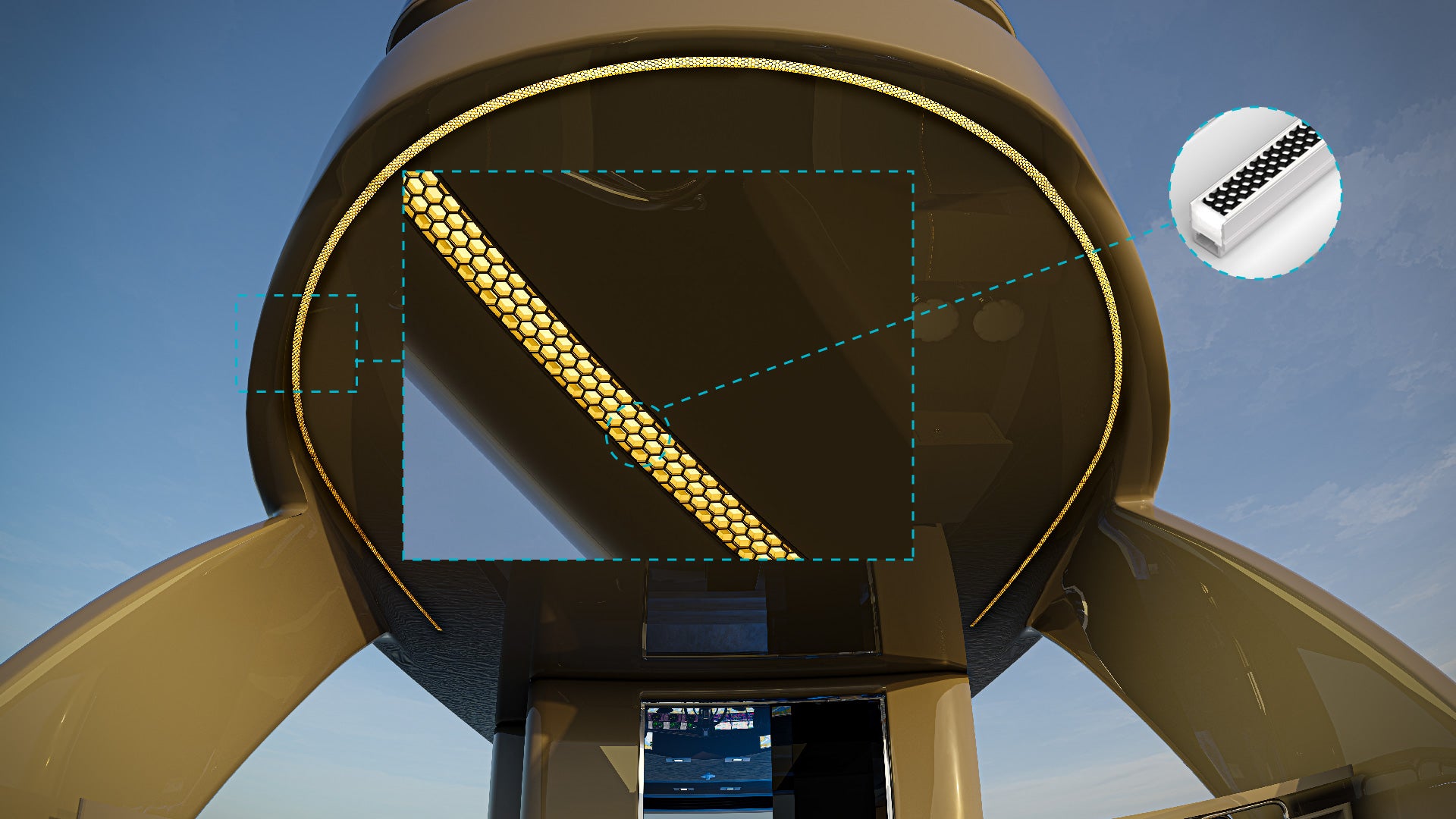

3D bend silicone lighting refers to strips that can bend in multiple directions, offering the highest level of flexibility. This type of bend is perfect for intricate designs and complex installations where both vertical and horizontal bending is required.

Advantages and Ideal Applications:

- Ultimate Flexibility: Can be shaped into virtually any form.

- Custom Installations: Ideal for creative and custom lighting projects.

- Complex Designs: Perfect for installations requiring both vertical and horizontal bends.

Example Applications:

- Artistic and sculptural lighting installations

- Custom signage with intricate designs

- Complex architectural lighting projects

Comparing the Bends

When choosing the right type of flexible silicone lighting for your project, consider the following factors:

Top Bend vs. Side Bend vs. 3D Bend:

- Flexibility: Top bend offers vertical flexibility, side bend offers horizontal flexibility, and 3D bend offers multi-directional flexibility.

- Application Suitability: Top bend is great for under-cabinet and vertical surfaces, side bend is ideal for signage and edge lighting, and 3D bend is perfect for custom and complex designs.

- Installation Complexity: Top and side bends are easier to install in straightforward applications, while 3D bends may require more planning and expertise.

Installation and Maintenance Tips

Installation Tips:

- Measure and Plan: Ensure accurate measurements and plan the installation path before starting.

- Proper Adhesion: Use appropriate adhesives and mounting clips for secure installation.

- Power Supply: Ensure a suitable power supply that matches the voltage requirements of the LED strips.

Maintenance Best Practices:

- Regular Cleaning: Keep the strips clean from dust and debris to maintain brightness.

- Inspect Connections: Regularly check the connections and wiring to prevent any issues.

- Avoid Overheating: Ensure proper ventilation to prevent overheating and extend the lifespan of the lights.

In summary, flexible silicone lighting offers a range of bending options to suit different applications, from top bend for vertical surfaces to side bend for horizontal edges, and 3D bend for complex designs. By understanding the characteristics and advantages of each type, you can make an informed decision to enhance your lighting projects.

Choosing the right type of bend for your flexible silicone lighting can transform any space, adding both functionality and aesthetic appeal. Whether you're illuminating a kitchen, creating stunning signage, or designing a custom lighting installation, flexible silicone lighting provides the versatility and durability needed for a successful project.

For high-quality Flexible Silicone Lighting Solutions, K2 Lighting provides a wide range of options tailored to meet your specific needs. Visit K2 Lighting to explore our offerings and transform your lighting designs.