Warehouse and industrial facilities demand effective lighting to ensure safety, productivity, and energy efficiency. LED lighting has emerged as the leading solution for these environments, offering significant cost savings, enhanced worker safety, and improved visibility for various tasks.

Energy Efficiency and Cost Savings

Reduced Energy Consumption in Large-Scale Facilities

Warehouse and industrial facilities require extensive lighting, often operating 24/7. LED lighting uses up to 75% less energy than traditional lighting systems like fluorescent or metal halide lights. This energy efficiency translates into significant cost savings, especially in large facilities where lighting constitutes a major part of operational expenses.

Long Lifespan and Reduced Maintenance Costs

LED lights have an exceptionally long lifespan—up to 25 times longer than conventional bulbs. This reduces the need for frequent replacements, lowering maintenance costs and minimizing disruptions to operations. In warehouses and industrial facilities where constant lighting is essential, the reduced maintenance of LEDs ensures consistent operation and maximizes productivity.

Supporting Sustainability Goals

Many warehouses and industrial facilities are adopting sustainable practices to reduce their carbon footprint. LED lighting supports these sustainability initiatives by consuming less energy, reducing greenhouse gas emissions, and being free of hazardous materials like mercury. This helps facilities meet their environmental goals while maintaining high-quality lighting.

Improved Safety and Visibility

Bright and Uniform Lighting for Warehouse Aisles and Workstations

Proper lighting is critical in industrial environments where precise tasks are performed and heavy machinery is operated. LED lighting provides bright, uniform illumination, improving visibility in warehouse aisles, loading docks, and workstations. This reduces the risk of accidents and errors, ensuring a safer working environment for employees.

Enhanced Security in Outdoor and Storage Areas

Outdoor areas such as loading bays, storage yards, and parking lots require adequate lighting to ensure safety and security, especially during nighttime operations. LED lighting offers bright, reliable illumination in these areas, helping to prevent accidents and improving security by deterring theft and vandalism. Motion-sensing LEDs can be used to activate lights only when needed, conserving energy while maintaining safety.

Emergency and Backup Lighting Systems

LED lighting is ideal for emergency lighting systems, such as exit signs and backup lights during power outages. LEDs are energy-efficient, reliable, and long-lasting, ensuring that critical lighting functions properly during emergencies, helping workers safely navigate the facility.

Enhanced Productivity and Worker Comfort

Reducing Eye Strain and Fatigue in Industrial Environments

In industrial settings, poor lighting can contribute to worker fatigue and eye strain, especially during long shifts. LED lights provide bright, flicker-free illumination, reducing eye strain and creating a more comfortable working environment. This leads to increased productivity, as employees can focus better and work more efficiently.

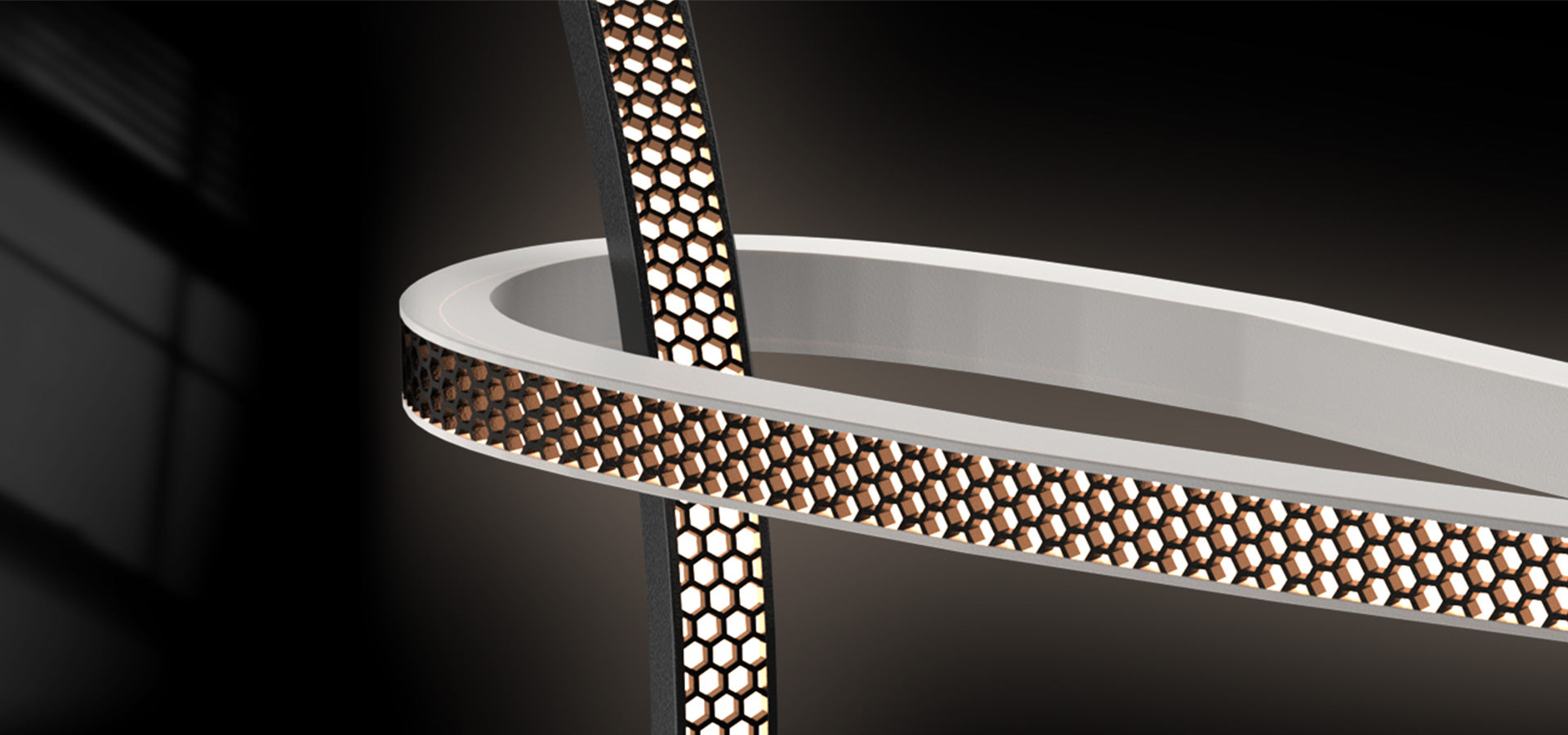

Creating Better Lighting for Detailed Tasks

In areas where detailed work is performed, such as assembly lines, quality control stations, and inspection areas, LED lighting can be customized to provide focused, high-intensity illumination. This ensures that workers have the visibility they need to perform tasks with precision, reducing errors and improving the overall quality of the output.

Dimmable Lighting for Flexible Workspaces

LED lighting systems offer the flexibility of dimmable lighting, allowing warehouse and industrial facility managers to adjust light levels based on the specific needs of different workspaces. This helps create comfortable lighting conditions that align with the tasks being performed, whether they require bright, focused lighting or softer, ambient lighting.

Versatile Applications Across Warehouse and Industrial Facilities

Tailored Lighting for Warehouse Storage Areas

In warehouse storage areas, proper illumination is crucial for ensuring that products are easily identifiable and accessible. LED lighting can be installed to provide uniform lighting across shelves, aisles, and storage racks, improving visibility for workers and reducing the risk of damage to products. Additionally, motion-activated LED lights in low-traffic areas can help conserve energy while maintaining functionality.

Lighting for Loading Docks and Outdoor Areas

Loading docks and outdoor work areas require reliable, weather-resistant lighting to ensure the safe loading and unloading of goods, especially in low-light conditions. LED lighting provides bright, durable illumination in these spaces, ensuring that workers can perform their tasks safely, regardless of the time of day or weather conditions. Outdoor LED lights are also designed to withstand harsh environmental factors, making them ideal for industrial settings.

Lighting for Industrial Machinery and Equipment Areas

In areas where heavy machinery is operated, LED lighting can be customized to provide focused, high-intensity illumination that enhances visibility and safety. This is particularly important in environments where precision is critical, such as manufacturing floors, assembly lines, or machine operation areas. Proper lighting reduces the likelihood of accidents and helps operators perform their tasks with confidence.

Sustainability and Environmental Responsibility

Reducing the Carbon Footprint of Industrial Facilities

Switching to LED lighting helps industrial facilities reduce their environmental impact by lowering energy consumption and greenhouse gas emissions. By adopting energy-efficient LED lighting, facilities can make significant progress toward their sustainability goals while maintaining the quality of lighting necessary for day-to-day operations.

Mercury-Free and Environmentally Safe Disposal

Traditional lighting systems, such as fluorescent or metal halide bulbs, often contain hazardous materials like mercury, which can be harmful to both the environment and facility workers. LED lights are mercury-free, making them safer to handle and dispose of, further supporting the facility’s commitment to environmental responsibility.

Better Technology Integration

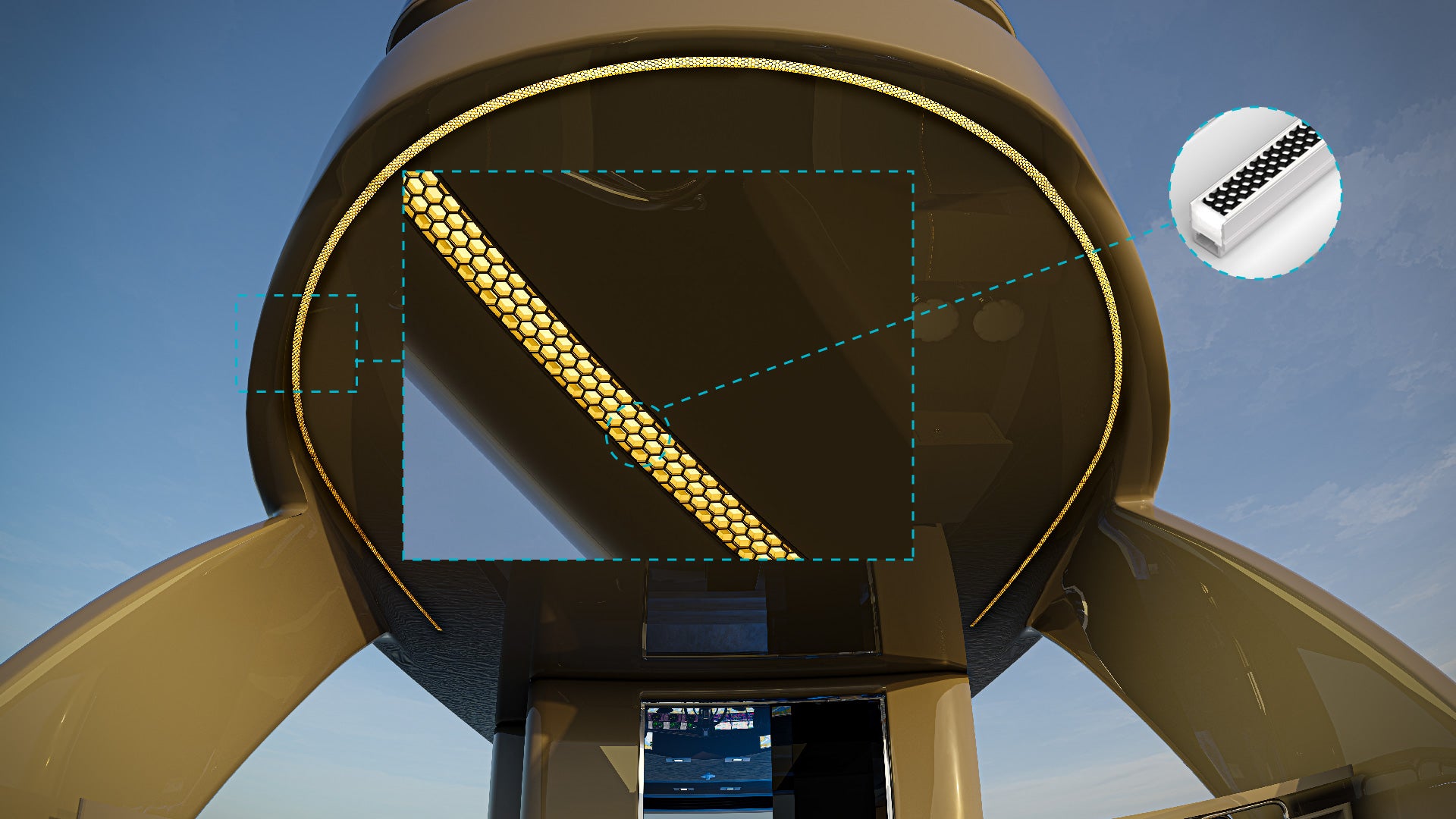

Smart Lighting Systems for Warehouse and Industrial Facilities

As industrial facilities embrace automation and smart technologies, LED lighting can be easily integrated into smart lighting systems. These systems allow facility managers to automate lighting schedules, adjust intensity, and monitor energy use in real-time. This reduces energy waste, optimizes lighting conditions for different tasks, and improves overall facility management.

Real-Time Monitoring and Automated Controls

Smart LED lighting systems offer real-time monitoring and automated controls, allowing facilities to adjust lighting based on occupancy, natural daylight levels, or specific operational needs. Automated lighting systems can help facilities reduce energy consumption, improve lighting efficiency, and provide valuable insights into energy usage patterns for better decision-making.

Conclusion

LED lighting is transforming warehouse and industrial facilities by offering energy efficiency, improving safety, and enhancing productivity. From lighting aisles and workstations to illuminating outdoor loading docks and storage areas, LED lighting provides a versatile, cost-effective solution that boosts operational efficiency while supporting sustainability goals. By adopting LED technology, warehouse and industrial facilities can reduce costs, improve worker safety, and create better working environments.