Marine LED lighting plays a crucial role in the safety, functionality, and aesthetics of various marine vessels, from small boats to large ships. However, the marine environment presents unique challenges, particularly the harsh effects of saltwater exposure. Saltwater, with its high salinity and corrosive nature, can significantly impact the performance and longevity of marine LED lighting systems.

In this blog, we will delve into how saltwater affects marine LED lights, the importance of choosing the right materials, protective measures, and maintenance practices, and provide insights from real-world examples to help you make informed decisions.

The Marine Environment: A Hostile Setting for Electronics

The marine environment is one of the most challenging settings for any electronic equipment. Constant exposure to water, humidity, and temperature fluctuations, combined with the presence of salt, creates a highly corrosive environment. Saltwater, in particular, is notorious for its ability to accelerate the degradation of materials and components. The ions in saltwater (mainly sodium and chloride) can easily penetrate and react with metals and other materials, leading to corrosion, rust, and ultimately, failure of the equipment.

For marine LED lighting, which often needs to operate reliably in such conditions, understanding these environmental factors is crucial. Whether it’s on a yacht, a fishing boat, or a commercial vessel, the LED lights must withstand the harsh realities of the ocean to ensure long-lasting performance.

Corrosion: The Primary Threat of Saltwater Exposure

Corrosion is the process by which metals deteriorate due to chemical reactions with their environment, and saltwater is particularly effective at accelerating this process. There are several types of corrosion that can affect marine LED lighting:

Galvanic Corrosion

This occurs when two different metals come into contact with each other in the presence of an electrolyte, such as saltwater. The more reactive metal (anode) corrodes faster than it would alone, while the less reactive metal (cathode) is protected. In LED lights, galvanic corrosion can occur at connection points where different metals are used, such as in housings and fasteners.

Pitting Corrosion

This localized form of corrosion creates small pits or holes in the metal surface. Pitting is particularly dangerous because it can penetrate deep into the metal, compromising the integrity of the component. This type of corrosion is common in stainless steel components if the protective oxide layer is damaged.

Crevice Corrosion

Occurs in confined spaces where saltwater can become trapped, such as under gaskets or within tight fittings. Over time, the stagnant saltwater becomes more concentrated, leading to accelerated corrosion in these areas.

Marine LED lights are particularly vulnerable to corrosion at their housings, connectors, and internal circuitry. If corrosion occurs on the LED’s circuit board or wiring, it can lead to short circuits, reduced light output, flickering, or complete failure of the light.

Impact on Performance and Longevity of Marine LED Lights

The corrosive effects of saltwater exposure can significantly impact the performance and longevity of marine LED lights. Here’s how:

Reduced Brightness and Efficiency

Corrosion on the LED’s lens or housing can block light output, reducing the brightness of the light. Additionally, if the LED’s circuitry is compromised, the light may not function at its full efficiency, leading to higher energy consumption and reduced light quality.

Flickering or Intermittent Operation

Corroded connectors and wiring can cause poor electrical connections, leading to flickering or intermittent operation of the LED lights. This can be particularly problematic in critical applications, such as navigation lights or deck lighting, where consistent performance is essential.

Premature Failure

Continuous exposure to saltwater without adequate protection can lead to the complete failure of the LED lights. This not only results in higher maintenance costs due to frequent replacements but also poses safety risks if the lights fail at critical moments.

When evaluating marine LED lighting options, it’s essential to consider the total cost of ownership, including potential maintenance and replacement costs due to saltwater exposure. Investing in high-quality, saltwater-resistant lighting systems can save money and hassle in the long run.

Protective Measures and Materials

To combat the corrosive effects of saltwater, marine LED lights must be designed with protective measures and materials that can withstand the harsh environment. Here are some key considerations:

Material Selection

The choice of materials used in the construction of marine LED lights is critical. Marine-grade stainless steel (such as 316 stainless steel) is often used for housings and hardware because of its high resistance to corrosion. Aluminum is also a popular choice due to its lightweight and corrosion-resistant properties, especially when coated with protective layers like anodizing or powder coating.

Protective Coatings

Applying protective coatings to metal surfaces can significantly reduce the risk of corrosion. Coatings such as epoxy, polyurethane, or powder coating provide a barrier that prevents saltwater from coming into direct contact with the metal. These coatings are particularly important for the housing and mounting brackets of LED lights.

Seals and Gaskets

Proper sealing is essential to prevent saltwater from entering the LED light’s internal components. High-quality gaskets and seals, made from materials such as silicone or rubber, are used to create watertight enclosures. It’s also important to ensure that these seals remain intact and are regularly inspected for wear and tear.

Ingress Protection (IP) Ratings

IP ratings indicate the level of protection an electronic device has against the intrusion of solids (like dust) and liquids (like water). For marine LED lights, a high IP rating (such as IP67 or IP68) is recommended. These ratings ensure that the lights are fully protected against water ingress, even during prolonged immersion in saltwater.

Best Practices for Maintaining Marine LED Lighting

Even with the best materials and protective measures, regular maintenance is crucial to ensure the longevity of marine LED lights. Here are some best practices:

Regular Cleaning

Salt deposits can accumulate on the surface of LED lights, leading to corrosion and reduced light output. Regular cleaning with fresh water can help remove these deposits and prevent damage. Avoid using abrasive materials or harsh chemicals that could damage protective coatings.

Inspections

Regular inspections of LED lights and their components can help identify early signs of corrosion or damage. Look for signs of rust, pitting, or wear on housings, connectors, and seals. Addressing these issues promptly can prevent more significant problems down the line.

Reapplying Protective Coatings

Over time, protective coatings can wear down, especially in harsh marine environments. Reapplying these coatings as needed can help maintain the integrity of the LED lights and extend their lifespan.

Proper Installation

Ensuring that LED lights are installed correctly can minimize their exposure to saltwater. For example, mounting lights in protected areas or using brackets that allow for easy drainage can help reduce the risk of water pooling and corrosion.

Saltwater is one of the most challenging aspects of the marine environment, and its impact on LED lighting cannot be underestimated. Corrosion, reduced performance, and premature failures are all risks that can be mitigated through the use of high-quality materials, protective measures, and regular maintenance. By understanding the effects of saltwater and taking proactive steps, marine operators can ensure that their LED lighting systems remain reliable and efficient for years to come.

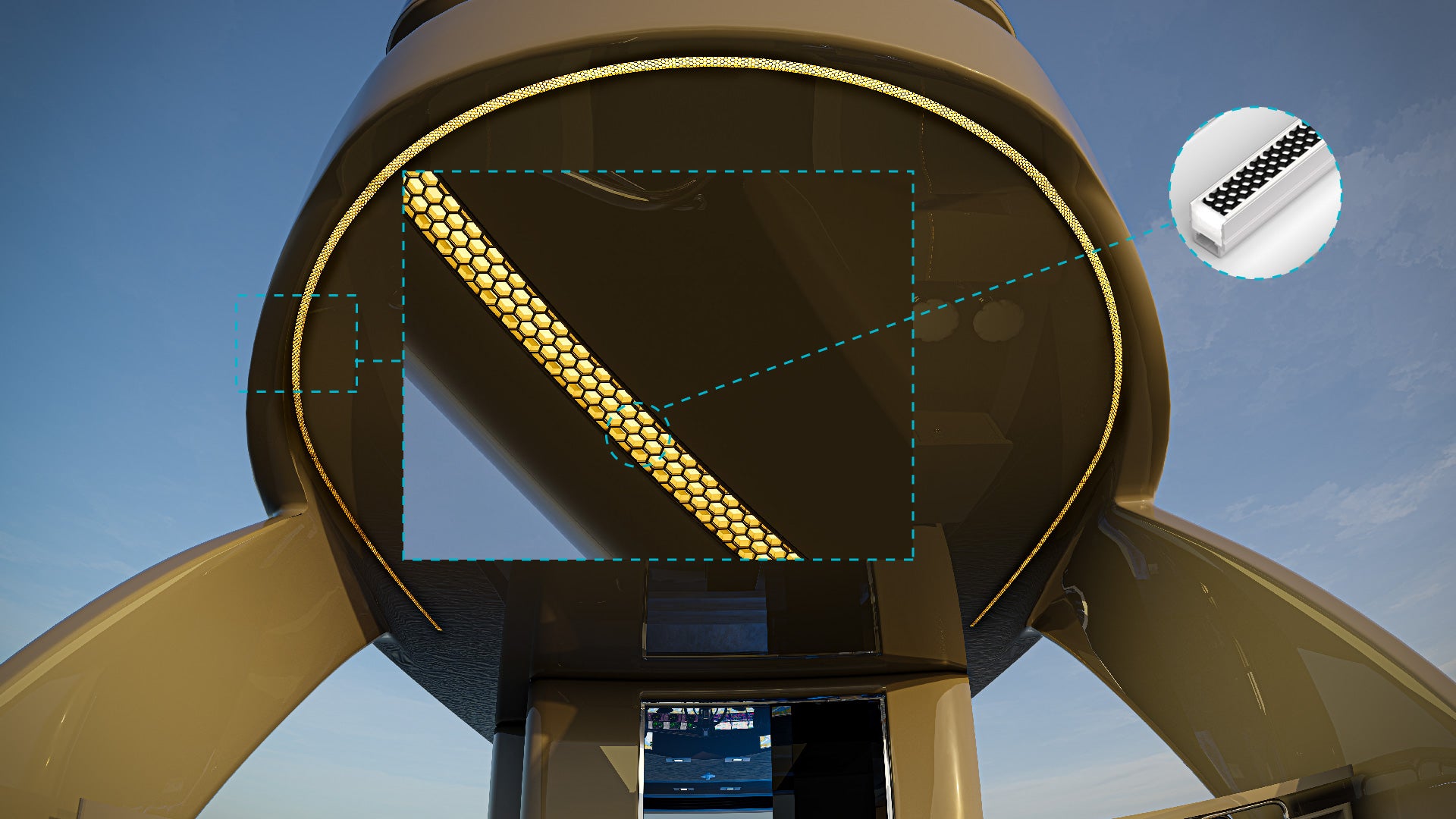

At K2 Lighting, we offer a range of marine LED lights specifically designed to withstand the harshest saltwater environments. Whether you’re outfitting a luxury yacht, a fishing boat, or a commercial vessel, our products are engineered to provide long-lasting performance and reliability. Visit our website to explore our selection of marine LED lights and learn more about how we can help you protect your investment in lighting systems.