Installing marine LED lights is more than just a simple DIY project; it requires careful planning and attention to detail to ensure that the lights function effectively and last for years. Improper installation can lead to various issues, including reduced performance, safety hazards, and increased maintenance costs. This blog will guide you through the most common mistakes people make when installing marine LED lights and provide expert tips on how to avoid them.

1. Choosing the Wrong LED Light for the Application

Marine LED lights come in various shapes, sizes, and specifications, each designed for specific purposes. Choosing the wrong type of light for your application can lead to inadequate illumination or even safety concerns.

Brightness (Lumens)

One common mistake is selecting LED lights that are either too dim or too bright for the intended use. For example, using a low-lumen light for navigation can make it difficult to see clearly, especially in low-light conditions. On the other hand, excessively bright lights in the cabin or cockpit can cause glare, making it uncomfortable and unsafe.

Beam Pattern

Another critical factor is the beam pattern. Spotlights with narrow beams are ideal for focused illumination, such as searching for objects in the water, while floodlights with wide beams are better suited for general area lighting on the deck. Using the wrong beam pattern can result in inefficient lighting, wasting energy and reducing visibility.

Color Temperature

The color temperature of LED lights affects how objects appear under their light. Cool white lights (5000K-6500K) are great for task lighting and visibility, while warm white lights (2700K-3000K) create a cozy ambiance in living spaces. Choosing the wrong color temperature can affect both functionality and comfort.

2. Ignoring IP Ratings and Waterproofing

The marine environment is harsh, with constant exposure to water, salt, and humidity. Therefore, it’s crucial to select LED lights that are specifically designed for marine use.

IP Ratings

IP (Ingress Protection) ratings indicate the level of protection an LED light has against solids (like dust) and liquids (like water). For marine environments, a high IP rating, such as IP67 or IP68, is essential. IP67-rated lights are protected against temporary submersion, while IP68-rated lights can withstand prolonged immersion. Using lights with insufficient IP ratings in areas exposed to water can lead to water ingress, causing short circuits, corrosion, and ultimately, failure of the lights.

Waterproofing Measures

It’s not just the lights themselves that need protection. All electrical connections, including wiring, switches, and junction boxes, must be waterproofed to prevent water ingress. A common mistake is using standard electrical connectors that aren’t rated for marine use, leading to potential failures down the line.

3. Incorrect Wiring and Electrical Connections

Proper wiring is crucial for both the safety and performance of your marine LED lighting system. Incorrect wiring can cause a range of issues, from dim lights to dangerous fire hazards.

Wire Size

Using undersized wires is a common mistake. LED lights, especially those installed far from the power source, require wires that can handle the electrical load without significant voltage drops. Undersized wires can cause the lights to dim, flicker, or not function at all. It’s essential to use the correct gauge wire for the length of the run and the current draw of the lights.

Quality of Connectors

Another mistake is using poor-quality connectors or failing to secure connections properly. In the marine environment, electrical connections are constantly exposed to moisture, which can lead to corrosion if not properly sealed. Using marine-grade connectors and ensuring that all connections are waterproof can prevent these issues.

Polarity Issues

LED lights are polarity sensitive, meaning they must be connected with the correct positive and negative terminals. Reversing the polarity can prevent the light from working or, worse, cause damage to the light or electrical system. Double-checking connections before powering on the system can prevent these costly mistakes.

4. Overlooking the Importance of Proper Mounting

The way you mount your marine LED lights can have a significant impact on their performance and longevity.

Secure Mounting

A common mistake is using inadequate mounting hardware, leading to loose or unstable lights. This is particularly problematic in the marine environment, where lights are subject to constant movement, vibrations, and shocks. If the lights aren’t securely mounted, they can become misaligned, reducing their effectiveness or even falling off entirely.

Mounting Location

Installing lights in locations that are prone to impacts or excessive vibrations is another common mistake. For example, placing lights in areas where they might be bumped by equipment or crew members can lead to damage. Similarly, installing lights near the engine or other sources of vibration can cause them to loosen over time. Choosing mounting locations that minimize these risks is crucial for ensuring the longevity of your LED lights.

5. Failing to Account for Voltage Compatibility

Marine LED lights come in different voltage ratings, most commonly 12V or 24V, depending on the electrical system of your boat. Using lights that are not compatible with your boat’s voltage can cause significant issues.

Voltage Mismatches

Installing a 12V light on a 24V system without a voltage regulator can result in immediate failure of the light. Conversely, installing a 24V light on a 12V system will result in dim or non-functional lights. It’s essential to verify the voltage requirements of your LED lights and ensure they match your boat’s electrical system.

Use of Voltage Regulators

If your boat has a mixed voltage system, or if you’re unsure about the voltage, using a voltage regulator or converter can ensure that your LED lights receive the correct voltage. This helps prevent damage to the lights and ensures consistent performance.

6. Not Considering Heat Management

While LED lights are known for their energy efficiency and low heat output compared to traditional bulbs, they still generate some heat, which needs to be managed, especially in the confined spaces often found on boats.

Heat Dissipation

Installing LED lights in enclosed spaces without proper ventilation can lead to overheating. Over time, excessive heat can damage the LED components, reduce the light’s lifespan, and cause the light output to degrade. This is particularly important in areas like engine rooms or other confined spaces where heat can build up.

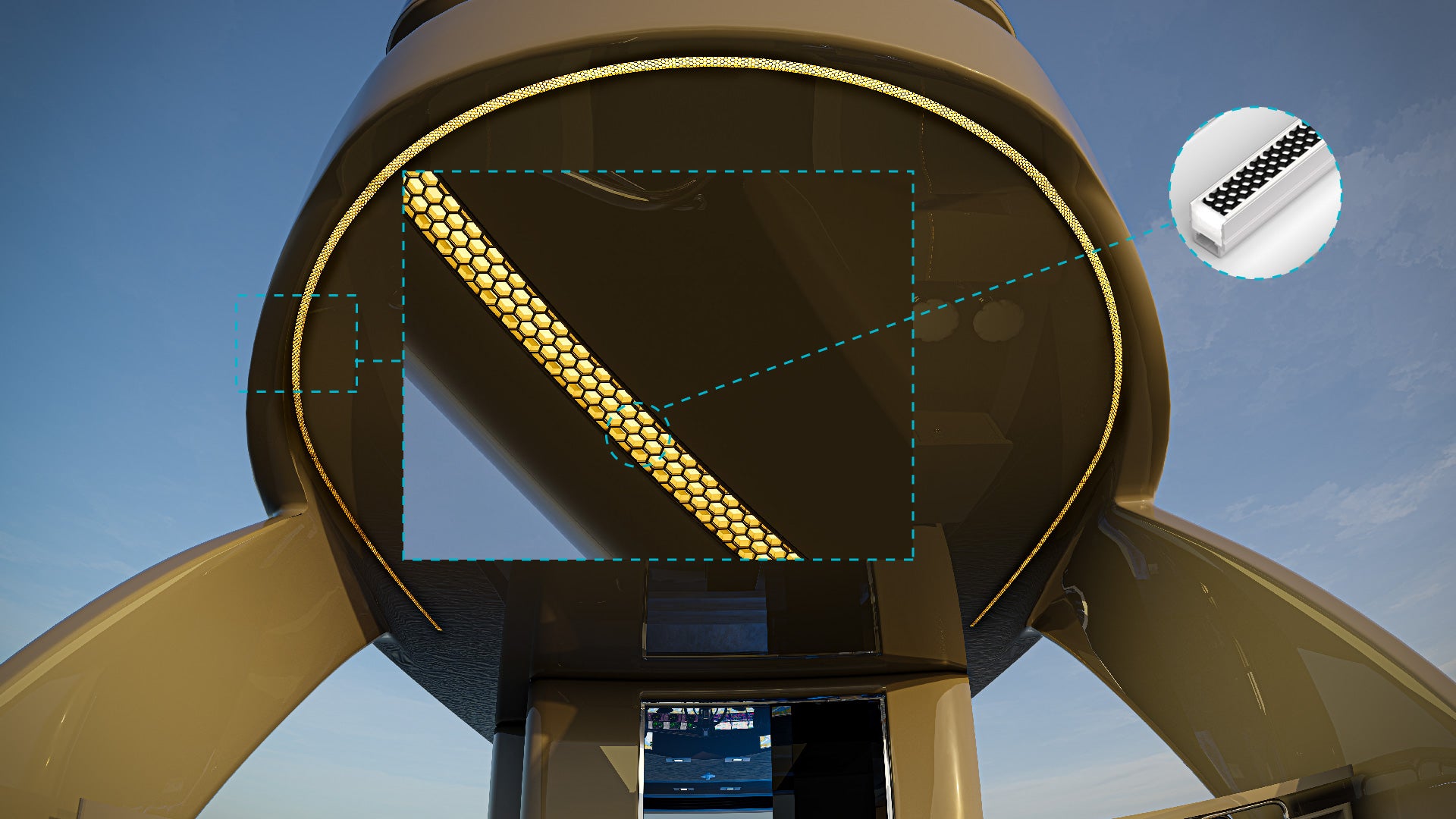

Built-in Heat Sinks

Many high-quality marine LED lights come with built-in heat sinks that help dissipate heat away from the light. Ensuring that these heat sinks are not obstructed and that there is adequate airflow around the light fixture is crucial for maintaining optimal performance and longevity.

7. Skipping Regular Maintenance After Installation

Once installed, it’s easy to forget about the maintenance of your marine LED lights, assuming they will continue to function without any attention. However, regular maintenance is essential to ensure their long-term performance.

Cleaning

Over time, salt, dirt, and grime can accumulate on the surface of your LED lights, reducing their brightness and effectiveness. Regular cleaning with fresh water can help remove these deposits and maintain optimal light output. Be sure to use non-abrasive cleaning tools to avoid damaging the light’s surface.

Inspection

Regularly inspecting your LED lights for signs of wear, corrosion, or water ingress can help catch potential issues before they become serious problems. Check the seals, gaskets, and connections to ensure they are still intact and functioning correctly. Addressing minor issues early can prevent costly repairs or replacements later.

Reapplying Protective Coatings

If your LED lights are exposed to harsh marine conditions, consider reapplying protective coatings to metal surfaces periodically. This can help prevent corrosion and extend the life of your lights.

8. Overlooking the Impact of Saltwater and Corrosion

Saltwater is one of the most corrosive elements in the marine environment, and it can have a significant impact on your LED lights if not properly addressed.

Corrosion-Resistant Materials

One of the most common mistakes is failing to choose LED lights made from corrosion-resistant materials. Marine-grade stainless steel, anodized aluminum, and other corrosion-resistant materials are essential for withstanding the harsh effects of saltwater. Using inferior materials can lead to rapid degradation and failure of the lights.

Protective Coatings and Seals

Even with corrosion-resistant materials, additional protective measures are often necessary. Applying protective coatings to metal surfaces and ensuring that all seals and gaskets are properly installed and maintained can help prevent saltwater from causing damage. Regularly inspecting these protective measures and reapplying coatings as needed can extend the life of your LED lights.

Installing marine LED lights is not just about choosing the right product; it’s about ensuring that every aspect of the installation is done correctly to avoid common pitfalls. From selecting the appropriate light for the application to ensuring proper wiring, mounting, and maintenance, attention to detail is key. By avoiding these common mistakes, you can ensure that your marine LED lights perform reliably and last for years, providing safety, functionality, and efficiency on the water.

K2 Lighting offers a wide range of marine LED lights designed to withstand the harsh marine environment and provide reliable performance. Whether you’re outfitting a small boat or a large vessel, our products are built with quality materials and engineering excellence. Visit our website to explore our selection of marine LED lights and get expert advice on installation and maintenance to ensure your lights perform at their best.